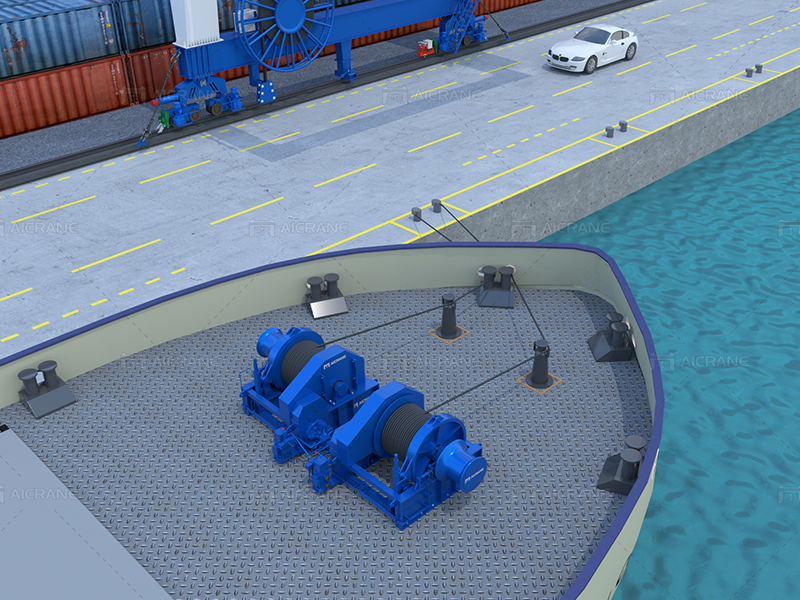

Hydraulic mooring winches play a crucial role in maritime operations, providing the necessary power and control for the safe and efficient mooring of vessels. These winches are essential for securing ships to docks or other structures, preventing drift and ensuring stability during loading and unloading operations. In this article, we will delve into the key components and their functions that make hydraulic mooring winches indispensable in the maritime industry.

Hydraulic Power Unit (HPU):

At the heart of every hydraulic mooring winch is the Hydraulic Power Unit (HPU). This component is responsible for generating hydraulic pressure that powers the winch system. The HPU typically consists of a hydraulic pump, motor, reservoir, and various control valves. It converts mechanical energy into hydraulic energy, providing the force needed to operate the hydraulic mooring winch.

Drum and Gypsy Head:

The drum is a central component of the mooring winch, around which the mooring line is wound. It is driven by the hydraulic motor and is designed to handle the tension and load exerted by the mooring line. Some winches also feature a gypsy head, which is a specialized drum designed for handling anchor chains. The combination of the drum and gypsy head allows for versatile mooring capabilities.

Braking System:

The braking system is crucial for controlling the release and retrieval of the mooring line. It ensures that the line is held securely when the winch is not in operation and can be released in a controlled manner when needed. Hydraulic mooring winches often employ disc brakes or band brakes to achieve precise and reliable braking performance.

Control System:

The control system of a hydraulic mooring winch is responsible for managing the entire operation. It includes various components such as control valves, joysticks, and electronic control panels. The control system allows operators to regulate the speed, direction, and tension of the mooring line, providing precise control over the mooring process.

Tension Monitoring System:

To ensure the safety of the mooring operation, mooring winches are equipped with tension monitoring systems. These systems measure the tension in the mooring line and provide real-time feedback to the operator. This information is crucial for preventing overloading and ensuring that the mooring process is within safe operating limits.

Emergency Release System:

In case of an emergency or unexpected situation, hydraulic mooring winches are equipped with emergency release systems. These systems allow for the rapid release of tension in the mooring line, ensuring the safety of both the vessel and the personnel involved in the operation.

Frame and Baseplate:

The frame and baseplate provide the structural support for the entire mooring winch system. They are designed to withstand the dynamic loads and forces exerted during mooring operations. The robust construction of these components is essential for the longevity and reliability of the hydraulic mooring winch.

Conclusion:

Hydraulic mooring winches are vital components in maritime applications, offering the power and precision required for safe and efficient vessel mooring. The integration of key components such as the Hydraulic Power Unit, drum, braking system, control system, tension monitoring system, emergency release system, and the frame/baseplate ensures a comprehensive and reliable mooring solution. As technology continues to advance, hydraulic mooring winches will likely see further improvements, enhancing their performance and expanding their applications in the ever-evolving maritime industry. To learn more, visit https://winchmachines.com/